Materials: Technical products

The information on this page is the first guideline in choosing the materials that are used in specific applications. This is general information, not guaranteed performance. It is the responsibility of the customer to determine the suitability of our products in a particular application.

Contact Butonia-Kahage Group if you require additional information.

===============================================================================================================================

Melamine

Melamine is a type of synthetic material made of natural materials that is produced in a similar way to how urea is produced. The most common use of this unbreakable and scratch resistant material is for plates, dishes, cups and mugs. Melamine is also suitable for buttons on workwear when high levels of hygiene and strength are demanded; some examples are nurses, doctors, laboratory technicians and craftsmen.

The base material is white; however solid colour material to match your fabric can be manufactured as it cannot be dyed. Designs, logos and company names can be pressed into the material or lasered or printed at the end of the production process. Laser and burn points are visible in white.

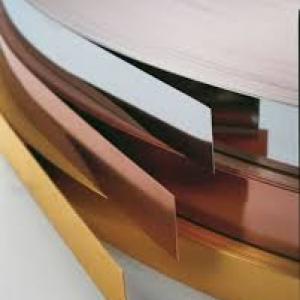

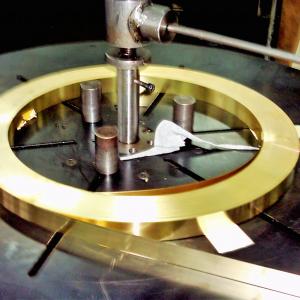

Brass and Stainless Steel

Brass is an alloy of copper and at most 40% zinc. Other metals can be added in minor amounts to acquire certain properties for processed alloys. If the zinc concentration is lower and another metal is the second component, then the alloy is not brass but bronze (with tin), nickel silver (with nickel), white tombac (with arsenic) or silicon tombac (with silicon). The material can be easily shaped and punched due to its flexibility and pliability. The oxidisation process can be stopped with coatings and galvanised metal colours; moreover, the appearance can be adjusted at will.

Stainless steel – stainless steel undergoes the same procedure as brass. However, no galvanising is necessary for stainless steel. It is an alloy of mainly iron, chrome, nickel and carbon.

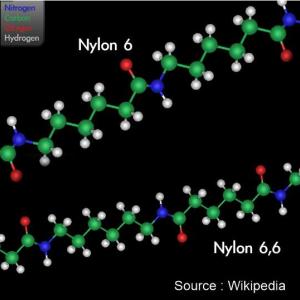

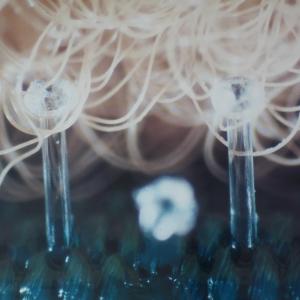

Polyamide / Nylon

Polyamide is a molecule consisting of amide monomers. Wool and cotton are examples of natural polyamides. Furthermore, countless synthetic materials made of polyamide exist with names such as Cordura, Kevlar, Nylon, Perlon and Tactel. The well-known nylon was used commercially for the first time in 1938 as bristles for toothbrushes. At the New York World's Fair in 1939 the famous women's stockings or 'nylons' were shown and sold worldwide from 1940 onwards. During the Second World War almost all of the nylon production was diverted to production of parachutes and parachute cords for the army. Nylon polymers have significant applications in textile and fibres (clothes, hook and loop, webbing, cords etc.), cast in shapes (for car parts, electrical appliances, clasps and accessories etc.) and foils (mostly for food). It has a high mechanical and thermal stability, increased deformation resistance, good sliding and tearing properties, high fracture and tension resistance, low moisture absorption and impact resistance.

Polyamide / PA 6.0 - PA 6.6

Two main types of polyamide are used for injection moulded parts:

PA6.0 is the most used material for. It has an excellent versatility, great impact resistance and is cheaper when compared to PA6.6.

PA6.6 is chemically comparable to PA6.0 but has a slight moisture absorption, is harder, more heat and tearing resistant and more protected against hydrolysis.

Extra additions are possible for both variants, like strengthening with glass fibre and with flame retardation (FR) if the product has to be able to withstand extreme applications. PA 6.0 and PA 6.6 generally have dimensional stability and are well resistant to ageing by heat, are very tough even at low temperatures and have an excellent cost-benefit ratio.

Polyester

Polyester is a polymer that can be processed thermoplastically (it melts when induced by thermal circumstances) and in a thermoset way (hardens by chemical reactions or thermal means) as well.

Polyester is thermoplastically processed into filaments by melt spinning for textile purposes. The elastic modulus is higher than that of polyamide. This makes polyester very suitable for mixing with fabrics which are not allowed to wrinkle and must stay in shape. Polyester absorbs almost no moisture in normal conditions. Polyester is resistant to acids, oxidizers, diluted lyes and sun rays. Bacteria and fungi do not harm the material. Polyester melts before it burns. The flame clearly creates soot and a hard brown pellet remains. The fibres/wires burn with a sweet scent and extinguish when the flame is removed. The melting point is around 255°C. The heat resistance of polyester is therefore better than that of polyamide 6.0 but around the same when compared to polyamide 6.6. Polyester is used in very different applications. Some technical textile applications: sail cloths for yachts, cables, conveyor belts, safety belts, webbing, cord and hook and loop.

A thermoset polyester is usually a liquid mixture of unsaturated polyester and styrene. These two components are able to react with eachother when induced by a hardener (a peroxide like dibenzoylperoxide or a different katalysator) to form a hard plastic which can be consequently processed into buttons, buckles and accessories. Read more at Fashion materials.

Polypropyleen

Polypropylene (pp) is a thermoplastic polymer with broad applications and is known under the name polypropene. Polypropylene can be synthesised in a very pure way and it can withstand chemical solvents, bases, acids and bacterial growth. The polymer can be moulded into a shape when it is hot, but it can also be cut/milled and welded. Polypropylene comes across our daily lives in forms of plastic bottles, carpets, plastic furniture, sail boats and in many car parts. Other uses are pipes, filter materials and plastic products which require higher quality. Polypropylene is also proccessed into ropes and cords. The material can be easily recycled.

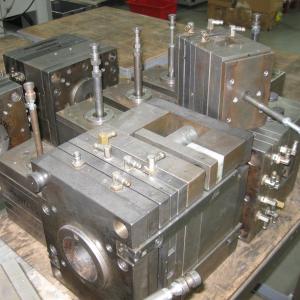

POM / Acetal

Polyoxymethylene (POM) is also known as Acetal, polyacetal and polyformaldehyde. It is a synthetic polymer that is used in precision parts which must be rigid, have low friction and excellent dimensional stability, even at low temperatures up to -40°C. Like other synthetic polymers, it is produced by different chemical manufacturers with slightly varying formulas and sold under names such as Delrin, Celcon, Ramtal, Duracon, Keptial and Hostaform. POM/Acetal has extraordinary resilient qualities which allow it to absorb heavy impacts and vibrations. Moreover, it absorbs little moisture and is resistant to oils and fuels.

POM is opaque white, but can be offered in all colours by adding pigments. Typical applications of injection moulded POM are high quality technical components like small gears, frames for glasses, ball bearings, ski bindings, fasteners, handles, lock systems, buckles and clasps (such as the side release and safety buckles) and other similar accessories.

Thermoplastisch Elastomeer

Thermoplastic elastomers (TPE), also known as thermoplastic rubbers, are a physical mix of polymers (mostly made of synthetic material and a rubber) that are elastic at room temperature. The material softens when heated which makes it easy to cast it into a mould. It retains this shape after cooling and can be reheated again to reshape it. TPE materials can be recycled in contrast to other 'normal' rubbers which are non-recycable due to their thermoset properties.

The two most important production methods are extrusion and injection moulding. The material can also be 3D printed. Manufacture by injection moulding is exceptionally fast, very economical and the products can be easily coloured with most pigments. TPE's have broad applications in the automobile sector, household appliances, electrical installations and cables, bags/suitcase accessories, shoulder pads and other protection items.